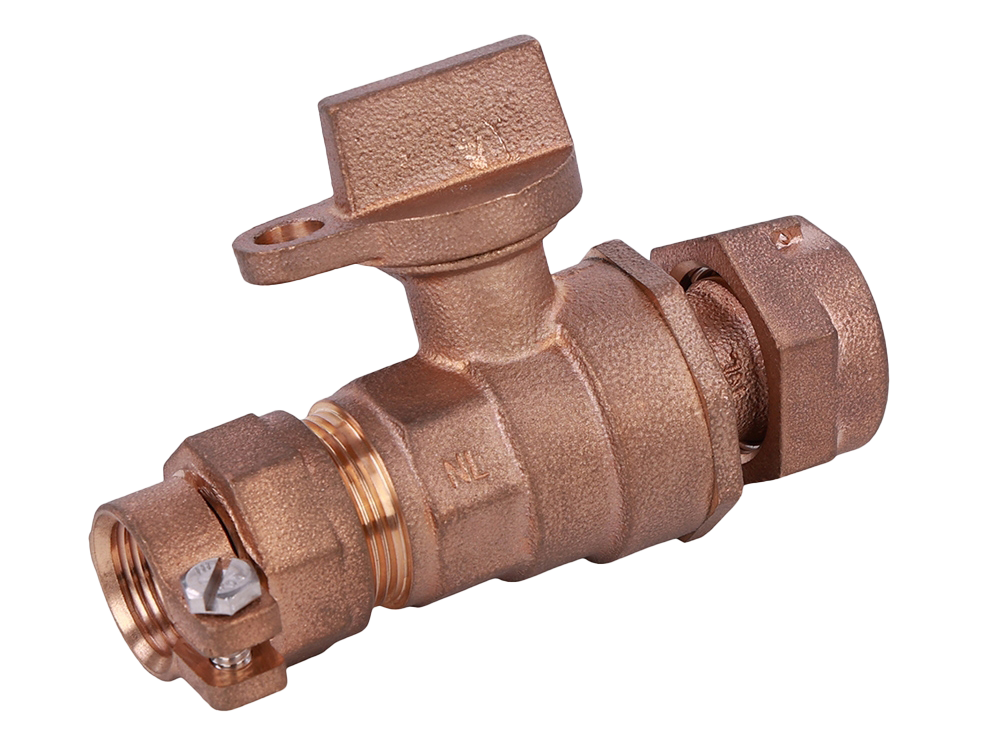

Lockable Ball Valves: Enhanced Safety, Durability, and Leak Prevention

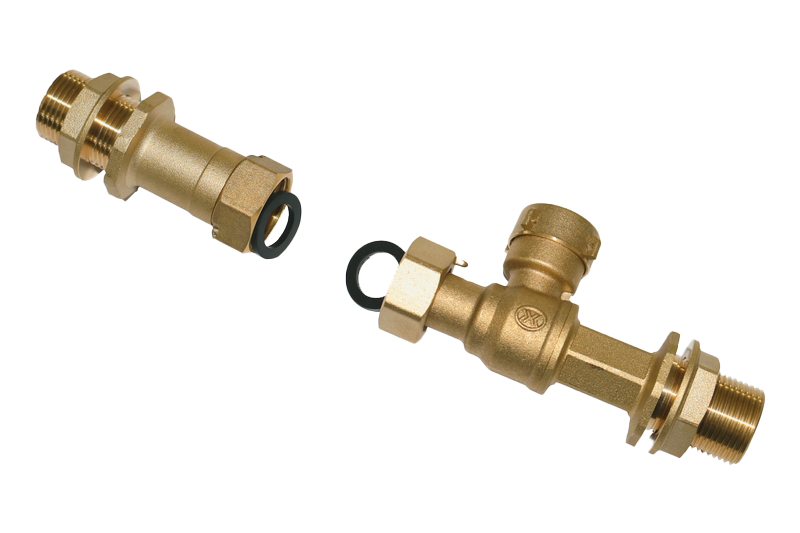

What is a Lockable Ball Valve?

A lockable ball valve is a type of valve that incorporates a locking mechanism to prevent the valve from being accidentally or unauthorizedly opened or closed. This added feature is particularly important in applications that require precise flow control and safety, such as gas pipelines or chemical processing.

A ball valve itself is a valve with a spherical closure element that controls the flow of fluid. When combined with a locking mechanism, it ensures that the valve remains in its desired position, whether it is fully open, partially open, or fully closed.

Sizes of Lockable Ball Valves

Common Sizes Available

Lockable ball valves come in a variety of sizes to suit different applications. The most common sizes range from 1/4 inch to 6 inches in diameter, with some manufacturers offering custom sizes for specific needs.

●Small-sized valves (1/4 inch, 1/2 inch) are often used in lower pressure applications, such as water filtration and HVAC systems.

●Medium-sized valves (1 inch, 2 inches) are used in commercial settings, such as plumbing and irrigation.

●Large-sized valves (3 inches and above) are used in high-pressure applications like oil and gas pipelines or large industrial machinery.

Choosing the Right Size

When selecting the appropriate size of a lockable ball valve, it’s crucial to consider factors such as:

●Flow rate requirements

●Pressure rating of the system

●Specific application needs (chemical, gas, liquid handling)

Advantages of Lockable Ball Valves

Improved Safety and Security

Enhanced Control

Durability and Longevity

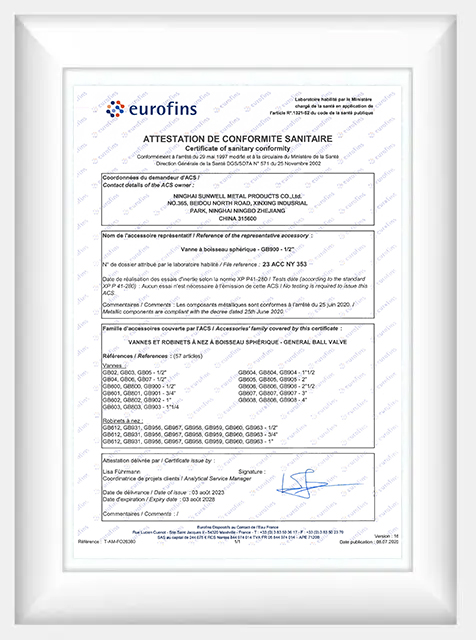

Compliance with Safety Standards

Cost Efficiency

Material and Performance of Lockable Ball Valves

Materials Used

The material choice for lockable ball valves impacts their durability, resistance to corrosion, and ability to withstand pressure. Common materials include:

●Stainless Steel: Known for its corrosion resistance and ability to withstand high temperatures and pressures.

●Brass: A more affordable option with good corrosion resistance, commonly used in lower pressure systems.

●Carbon Steel: Offers high strength and durability in harsh environments, often used in heavy industrial applications.

Performance Features

Lockable ball valves are designed to perform under varying pressure and temperature conditions. Some key performance features include:

●Pressure Rating: Valves are rated for different pressure limits, and selecting the right one is crucial to ensure safe operation.

●Temperature Resistance: The ability to withstand extreme temperatures, either hot or cold, is another critical factor in performance.

●Flow Rate Compatibility: The valve must be compatible with the required flow rate to ensure efficient operation.

Applications of Lockable Ball Valves

Industrial Applications

Lockable ball valves are used across a wide range of industries, including:

●Oil and Gas: Used to control the flow of gas or liquid hydrocarbons safely.

●Water Treatment: Ensures that valves in water purification systems remain securely in place to prevent contamination.

●Pharmaceuticals: Used in systems where precise flow control is essential to prevent contamination or maintain sterile environments.

●Chemical Processing: Helps in controlling and preventing leaks in highly sensitive environments.

Specific Use Cases

Lockable ball valves are crucial in applications like:

●Pipeline Systems: Ensuring that pipelines carrying hazardous materials or gases are properly sealed and cannot be tampered with.

●Pressure Relief Systems: Locking mechanisms can prevent inadvertent opening of relief valves, avoiding system malfunctions.

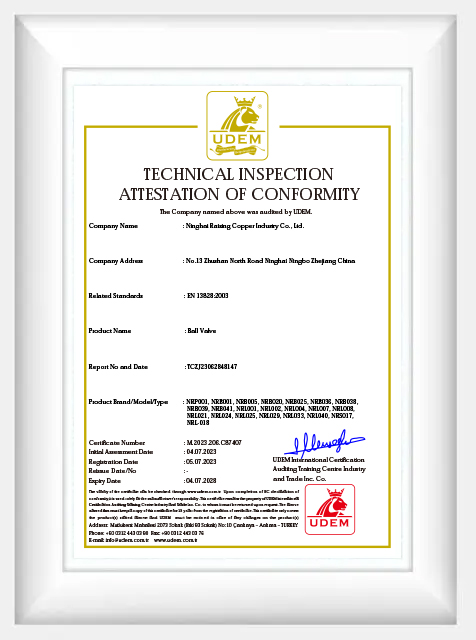

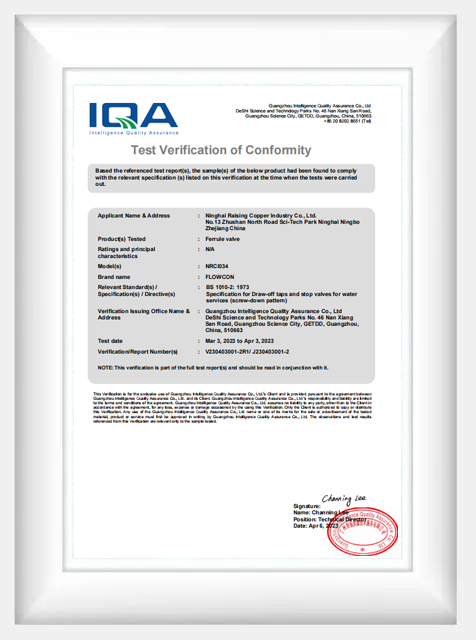

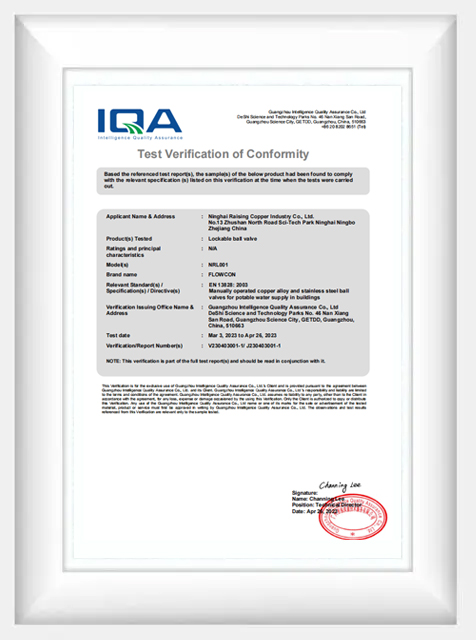

Lockable Ball Valve Inspection Report

Why Choose Our Lockable Ball Valves?

Introduction to Our Brand

Product Quality and Reliability

Advantages of Our Products

Customer Testimonials

Warranty and Support

FAQs

What is the difference between a lockable ball valve and a standard ball valve?

A lockable ball valve has an added locking mechanism that prevents unauthorized operation, whereas a standard ball valve does not.

How do you lock a ball valve?

To lock a ball valve, simply engage the locking mechanism, either by inserting a key or using a manual latch, depending on the design.

Are lockable ball valves suitable for high-pressure systems?

Yes, lockable ball valves are available in pressure-rated versions suitable for high-pressure systems.

How long do lockable ball valves last?

With proper maintenance, lockable ball valves can last for many years, typically 10–20 years, depending on usage and material.